How to Select the Right Load Turning Device for Steel Mills

In the process of steel production and processing, workpieces such as steel plates, steel coils, section steels and welded components are usually heavy and large-sized, and often require turnover or posture adjustment between different processes. An improper turnover method will not only affect production efficiency, but also lead to serious potential safety hazards. Therefore, selecting suitable set of load turning device has become a key factor for steel mills to improve their automation level and safe production capacity.

Clarify the Application Condition Requirements of Steel Mills

Types of workpieces to be turned: Steel plates, steel coils, section steels, welded structural components or large castings

Weight range per unit: Ranging from several hundred kilograms to tens of tons

Turnover angle requirements: 90°, 180°, 360° or a specified angle

Frequency of use: High-frequency continuous operation

Operating environment: High-temperature, dusty and oily conditions

Select the Appropriate Turnover Type According to Workpiece Characteristics

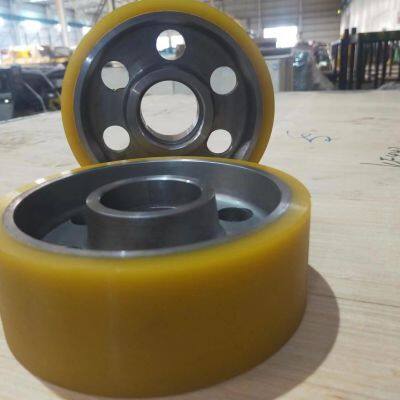

Belt turning device: Adopts high-strength fiber belts made of composite materials as slings to protect workpieces from damage.

Chain turning device: Uses high-strength wear-resistant chains as slings, which can steadily turn large castings.

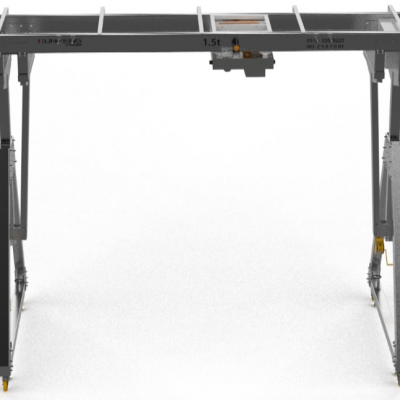

Suspension load tuning units: Usually used in conjunction with overhead cranes or gantry cranes.

Focus on Load Capacity and Safety Design

Whether the rated load and safety factor are sufficient

Whether it is equipped with anti-slip, anti-falling and misoperation prevention designs

Whether it is configured with mechanical limit, electrical limit and emergency stop functions

Whether the turnover process is stable, avoiding impact and swinging

It is particularly important to select a manufacturer with customized design capabilities and project experience in the steel industry. KUNFENG CRANES can provide one-stop services from working condition evaluation and scheme design to transportation. Welcome to contact us for customized solutions and product quotes that meet your production and application needs.